The history of trade dates back thousands of years before containerisation. People traded across oceans and lands, sailing the world in search of various goods and commodities that their countries did not have, everything from traded food, jewels and materials to new treasures.

The history of trade dates back thousands of years before containerisation. People traded across oceans and lands, sailing the world in search of various goods and commodities that their countries did not have, everything from traded food, jewels and materials to new treasures.

Shipping before 1850 was difficult, expensive, and irregular, dominated by wooden ships using sails propelled only by wind. Later, the development of steamships made transportation cheaper and less risky. Getting goods on and off ships has historically been a bottleneck. A large part of the cost of international trade was taking the cargo off the ship, sorting it out, and dealing with the pilferage that took place along the way. Therefore the advent of containerisation brought about a massive transformation.

Containerisation has its origins in early coal mining regions in England from the late 18th century onwards. By the 1830s, railroads on several continents were carrying containers that could be transferred to other modes of transport. Before World War II, US, British and French railway companies experimented with methods of sealing goods in different sizes and shapes of boxes before transporting them. However, lack of specialised equipment like cranes for loading and unloading cargo combined with resistance from unions made it difficult for the development of container shipping till 50’s.

During World War II, the United States used specialised containers to speed the loading and unloading of transport ships. These reusable containers were used for shipping household goods of officers.

In 1955, former trucking company owner Malcom McLean worked with engineer Keith Tantlinger to develop the modern intermodal container. The challenge was to design a shipping container that could efficiently be loaded onto ships and held securely on long sea voyages. The result was an 8 ft. tall by 8 ft. wide box in 10 ft. long units constructed from 2.5 mm of thick corrugated steel. The design incorporated a twist lock mechanism atop each of the four corners, allowing the container to be easily secured and lifted using cranes. On April 26th 1956, McLean put 58 containers on board a refitted tanker ship, SS Ideal X and sailed them from Newark to Houston.

The immediate result of the first US container journey was a substantial saving in the cost associated with moving cargo piece by piece from truck or railcar from the warehouse, onto the ship, and then unloading at the destination port, to the warehouse and then again on the truck or railcar. Containerisation revolutionised this multiple handling of cargo by increasing port labor productivity through mechanised loading and unloading of containerised cargos.

The 1956 container operation by the Ideal X involved a ship and cranes that were designed for other purposes. Three years later the industry saw additional savings through the building of purpose-built container cranes followed by the large purpose-built containerships.

The 1956 container operation by the Ideal X involved a ship and cranes that were designed for other purposes. Three years later the industry saw additional savings through the building of purpose-built container cranes followed by the large purpose-built containerships.

From a transportation technology perspective, containerisation resulted in the introduction of intermodal freight transport, since the shipment of a container can use multiple modes of transportation -ship, rail or truck- without any handling of the freight when changing modes.

It was a logical next step that container sizes could be standardised so that they could be most efficiently stacked and so that ships, trains, trucks and cranes at the port could be specially fitted or built to a single size specification. This standardisation eventually spread across the global industry.

To realise intermodal cargo transport, all areas of the transport chain had to been integrated. It was not simply a question of putting cargo in containers. The ships, port terminals, trucks and trains had to been organised and adapted to handle the containers.

In 1956, the UN Economical Commission for Europe defined a container transport unit with characteristics later reformulated by ISO – as a transport equipment of permanent character suitable for repeated use, designed to suit multiple modes of car without having to restuff, fitted with devices permitting its ready handling, particularly its transfer from one mode of transport to another, designed to be easy to fill and empty, having an internal volume of 1m3 (35.3 ft.3) or more’.

These containers were only a box of different sizes. It was only in 1970 that the sizes were standardised. The 20-foot container, referred to as a twenty-foot commodities equivalent unit (TEU) became the industry standard reference with cargo volume and vessel capacity now measured in TEU. The 40-foot length container – literally 2 TEU – became known as the Forty-foot Equivalent Unit (FEU) and is the most frequently used container today even though the industry primarily refers to handling and capacity by TEU.

Various types of specialised container types also emerged over time, notably the ‘reefer’ for temperature controlled cargoes and various types of equipment capable of unitising odd sized (OOG), heavy cargoes, as well as liquefied commodities.

Containerisation gave birth to a new era of improved efficiencies – meaning that the ships spent less time in ports, had shorter transit times, used less labour and increased customer efficiencies since they could meet stock requirements on time. The containers also reduced damage and pilfering and also made documentation easier.

Since the 1950’s, containerships have evolved tremendous , from the Ideal X’s to 3000 TEU capacity vessels in 70’s, 4,000 in 80’s, 7,000 in 90’s, 16000 TEU vessels currently sailing.

The need for even greater efficiency and capacity has led to the next generation of mega ships – the Triple E’s; which will come into service this month capable of carrying 18,000 TEU – three times as many as the biggest container ships 15 years ago.

October invariably is a hectic time for our Sales teams, as preparations are in full swing for the approaching Sales Strategy Meet in November. As rightly said by Sir Winston Churchill “However beautiful the strategy, you should occasionally look at the results.” The time of the year has arrived for all of us at CSS to sit together and review what we have achieved through our past strategy and formulate new strategic plans to move ahead.

October invariably is a hectic time for our Sales teams, as preparations are in full swing for the approaching Sales Strategy Meet in November. As rightly said by Sir Winston Churchill “However beautiful the strategy, you should occasionally look at the results.” The time of the year has arrived for all of us at CSS to sit together and review what we have achieved through our past strategy and formulate new strategic plans to move ahead. I

I CSS Group recently visited the offices of IFS International Forwarding S.L in Spain as part of its strategy to continuously develop and expand its NVOCC routes. Representing CSS Group was Siby C. Kurian, Senior General Manager, Sales & Marketing, CSS, who met with Antonio J. Aznar, Foreign Development & Documentation for IFS.

CSS Group recently visited the offices of IFS International Forwarding S.L in Spain as part of its strategy to continuously develop and expand its NVOCC routes. Representing CSS Group was Siby C. Kurian, Senior General Manager, Sales & Marketing, CSS, who met with Antonio J. Aznar, Foreign Development & Documentation for IFS. With over 25 years of experience in the international market, IFS currently owns and operates offices in Spain, Portugal, Mexico and Morocco, each with their own warehouse and has an extensive network through their agents thus providing unparrelled support in those regions.

With over 25 years of experience in the international market, IFS currently owns and operates offices in Spain, Portugal, Mexico and Morocco, each with their own warehouse and has an extensive network through their agents thus providing unparrelled support in those regions. CSS Projects, Oil & Energy recently handled and successfully delivered 12 skids, each weighing more than 33 tonnes to their final destination in Yemen. All of the 12 skids were loaded using 200 tonne cranes onto low bed trailers and were lined up in the loading area for onward road transportation. The entire operation was undertaken and supervised by the CSS Projects team to ensure the project was undertaken seamlessly with no delays encountered as it was a highly time sensitive and critical cargo.“The fact that the entire cargo was delivered to its final destination in 9 days is evidence of the hardwork and commitment the team at CSS Projects puts in regardless of the type of cargo, or its final destination. I would like to extend congratulations to the entire team for a job well done,” said Raj George, Senior VP, Projects, Oil & Energy, CSS.

CSS Projects, Oil & Energy recently handled and successfully delivered 12 skids, each weighing more than 33 tonnes to their final destination in Yemen. All of the 12 skids were loaded using 200 tonne cranes onto low bed trailers and were lined up in the loading area for onward road transportation. The entire operation was undertaken and supervised by the CSS Projects team to ensure the project was undertaken seamlessly with no delays encountered as it was a highly time sensitive and critical cargo.“The fact that the entire cargo was delivered to its final destination in 9 days is evidence of the hardwork and commitment the team at CSS Projects puts in regardless of the type of cargo, or its final destination. I would like to extend congratulations to the entire team for a job well done,” said Raj George, Senior VP, Projects, Oil & Energy, CSS. T

T E

E

An innovative HR Programme at CSS Delhi

An innovative HR Programme at CSS Delhi T

T The 1956 container operation by the Ideal X involved a ship and cranes that were designed for other purposes. Three years later the industry saw additional savings through the building of purpose-built container cranes followed by the large purpose-built containerships.

The 1956 container operation by the Ideal X involved a ship and cranes that were designed for other purposes. Three years later the industry saw additional savings through the building of purpose-built container cranes followed by the large purpose-built containerships. Cold Chains are temperature controlled supply chain intended to optimize product quality and cost for specific commodities while minimizing wastage. CSS Group has now been setup to handle refrigerated cargo as a first step towards building an unbroken cold chain. Recent investment in technically adept personnel in addition to leveraging on new partner strengths overseas, CSS will now actively pursue temperature controlled commodities both for sea and air.

Cold Chains are temperature controlled supply chain intended to optimize product quality and cost for specific commodities while minimizing wastage. CSS Group has now been setup to handle refrigerated cargo as a first step towards building an unbroken cold chain. Recent investment in technically adept personnel in addition to leveraging on new partner strengths overseas, CSS will now actively pursue temperature controlled commodities both for sea and air. Onam is reminiscent of Kerala’s agrarian past; the harvest festival falls during the Malayalam month of Chingam (Aug – Sep) and marks the homecoming of the mythical King Mahabali who Malayalees consider as their King.

Onam is reminiscent of Kerala’s agrarian past; the harvest festival falls during the Malayalam month of Chingam (Aug – Sep) and marks the homecoming of the mythical King Mahabali who Malayalees consider as their King. Under the patronage of His Excellency Sheikh Nahyan Bin Mubarak Al Nahyan, Minister of Culture, Youth and Social Development, Chairman of the General Authority for Youth and Sports Welfare, the Dubai Multi Commodities Centre (DMCC) Kobe Bryant Health and Fitness Weekend in support of diabetes awareness was held at the American University in Dubai (AUD) on September 27th, 2013.

Under the patronage of His Excellency Sheikh Nahyan Bin Mubarak Al Nahyan, Minister of Culture, Youth and Social Development, Chairman of the General Authority for Youth and Sports Welfare, the Dubai Multi Commodities Centre (DMCC) Kobe Bryant Health and Fitness Weekend in support of diabetes awareness was held at the American University in Dubai (AUD) on September 27th, 2013. Sponsored by CSS Group, the “HEXA Onam” celebration 2013, held at Family Palace Restaurant in Sharjah, UAE was a great success as they organized various cultural programs in honour of the Onam festival. HEXA, (Haripad Expatriates Association) had arranged performances that included, Thiruvathira, classical dances, cinematic dances, film songs, the Pookkalam and Maveli. The Maveli of HEXA Onam 2013 was none other than Swan Chacko, Operations Supervisor, CSS Projects, Oil & Energy division. Also in attendance was Shelly V. John, Manager Admin, CSS.

Sponsored by CSS Group, the “HEXA Onam” celebration 2013, held at Family Palace Restaurant in Sharjah, UAE was a great success as they organized various cultural programs in honour of the Onam festival. HEXA, (Haripad Expatriates Association) had arranged performances that included, Thiruvathira, classical dances, cinematic dances, film songs, the Pookkalam and Maveli. The Maveli of HEXA Onam 2013 was none other than Swan Chacko, Operations Supervisor, CSS Projects, Oil & Energy division. Also in attendance was Shelly V. John, Manager Admin, CSS. The United Arab Emirates (UAE) has now become an important global hub for the people in the Shipping Industry. To arrest a vessel is a statutory right of a claimant under the UAE Maritime Code No. 26 of 1981, as amended (The ‘Maritime Code’). It provides and regulates the arrest of vessels.

The United Arab Emirates (UAE) has now become an important global hub for the people in the Shipping Industry. To arrest a vessel is a statutory right of a claimant under the UAE Maritime Code No. 26 of 1981, as amended (The ‘Maritime Code’). It provides and regulates the arrest of vessels. Whilst the UAE is not a signatory to the above conventions, the UAE Maritime Code borrows largely from the Hague-Visby Rules and relevantly incorporates, by way of example, the carrier’s obligation to exercise due diligence to make the vessel seaworthy, the Hague-Visby force majeure- type defences to the breach of the sea-worthiness obligation and package limitation.

Whilst the UAE is not a signatory to the above conventions, the UAE Maritime Code borrows largely from the Hague-Visby Rules and relevantly incorporates, by way of example, the carrier’s obligation to exercise due diligence to make the vessel seaworthy, the Hague-Visby force majeure- type defences to the breach of the sea-worthiness obligation and package limitation. D

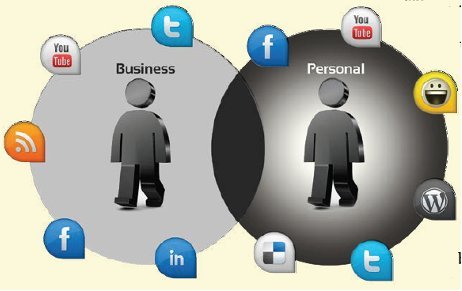

D As part of our continuous commitment to the freight forwarding fraternity, CSS initiated a thank you scheme over 6 years ago, whereby one lucky name out of the scores of business cards that are dropped into the raffle bowls placed at the Delivery Order Counter will be rewarded with a gift.

As part of our continuous commitment to the freight forwarding fraternity, CSS initiated a thank you scheme over 6 years ago, whereby one lucky name out of the scores of business cards that are dropped into the raffle bowls placed at the Delivery Order Counter will be rewarded with a gift.